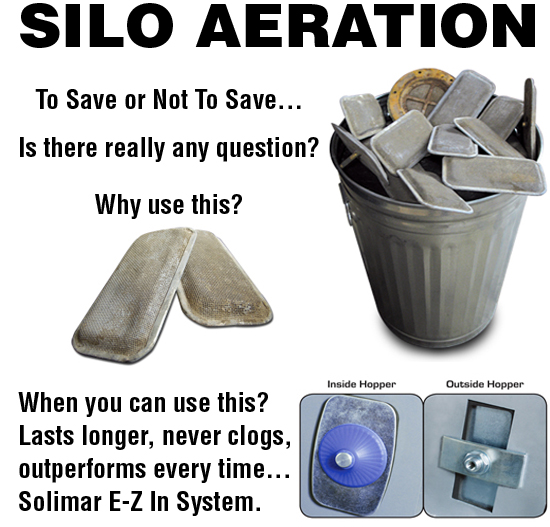

Today’s aeration technology renders screen and fabric pads obsolete. Solimar Fluidizers rarely need replacing, never clog and provide years of maintenance-free service. That means a fast return on your investment (payback within one or two change outs of pads) and thousands of dollars of savings over the years. Pads are a 40-year design that cost less but are a classic case of “You Get What You Pay For.”

Here’s how you save:

- No downtime to replace/restore aeration

- No labor costs to replace clogged pads

- Reduced potential of accidents

From the first day of use, air pads performance begins to deteriorate due to ‘fines’ clogging the pad’s pores.This reduces performance and increases energy consumption. But what is the biggest killer of pads? Moisture. Inevitably moisture from the airline will cause the pad to clog, reducing aeration while reducing flow.

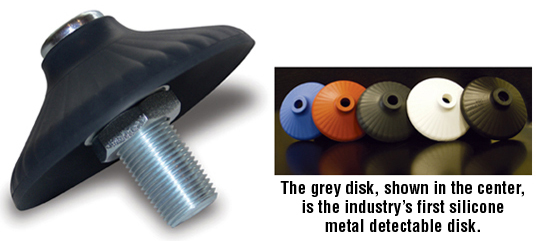

Solimar Fluidizers are unaffected by moisture and impart vibration to the silo wall to assist in material flow. The disk material will not tear or degrade keeping your dry product moving without contamination. Want a little more security? Order our metal detectable disk when zero contamination is a must.

Pad replacement with Solimar disks is easy using existing pad cut-outs. No cutting or drilling is required with our E-Z In system. Now your personnel are free to do more important tasks while maintenance costs are reduced because Solimar disks come with a two-year performance guarantee.

Call or e-mail to discover your cost savings by switching to Solimar Fluidizers today. The only question is how much will you save?