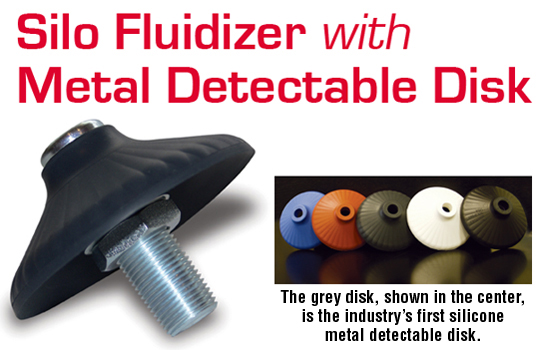

In the food industry, manufacturers are looking for the highest purity for their product. In response to their requests, we developed the first Metal Detectable Fluidizer Disk.

This Solimar innovation has been well received by our customers, with many commenting there is a need to be able to assure zero contamination from their aeration. Instances of Solimar fluidizer disks contaminating product are extremely rare, but disks that have been mechanically damaged during bin cleaning, by extreme air pressures or improper installation could potentially cause a problem.

Now customers can have both a ‘belt and suspenders’ to provide another level of protection and safety for their products.

Meanwhile they enjoy all the benefits of Solimar Fluidizers, including:

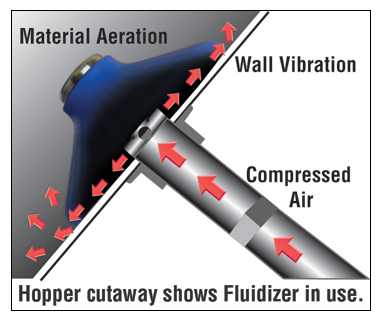

• Aeration loosens up the product for better flow. Minimum back pressure puts air energy where it is needed the most – in the silo, bin or hopper.

• Directional Air Flow. The Fluidizer disk forces air to move along the bin wall freeing up product and assuring good cleanout.

• Gentle Vibration keeps the product flowing without allowing it to compact or plug.

• No Airline Plugging. Disk seals tightly against the silo wall and prevents airline plugging.

• Robust Design. The disk will not tear, pick up moisture and is unaffected by temperatures up to 350 F (170 C).

• Material Compatible. Available in FDA approved silicone rubber in blue and white, FDA approved EPDM rubber in black or white, also Orange High Temp rubber, and now FDA approved grey Metal Detectable

Contact our engineers with your product flow requirements and purity concerns to discover how Solimar Aerators can benefit your process.

Engineering Assistance. Fax or e-mail a sketch or drawing of your chamber, along with a description of your bulk material and we will provide a recommended number and placement of Fluidizers for your application the next day.